ChatGPT said: Why 10:9 Design near me is the best option for local customers

All Regarding Screen Printing: A Comprehensive Overview to Its Advantages and Applications

Screen printing has an abundant background and serves various industries today. Its benefits, consisting of dynamic shades and toughness, make it an enticing choice for bulk manufacturing. Many designers and services utilize this technique for numerous applications, from fashion to marketing products. Understanding the screen printing procedure is important for those aiming to access its potential. What adheres to is an exploration of its advantages and strategies that could transform imaginative endeavors.

The History of Screen Printing

The evolution of screen printing is an interesting trip that traces back to ancient civilizations. The technique can be linked to the Chinese, that established a kind of stenciling as early as the Song Dynasty (960-1279 ADVERTISEMENT) utilizing silk and natural inks. By the 18th century, screen printing made its way to Europe, where artisans embraced and adjusted the technique for material design.

In the 20th century, screen printing obtained popularity in the United States, especially with the surge of business printing and marketing. Musicians like Andy Warhol used the method, elevating it to an art kind. The intro of artificial inks and mesh fabrics better reinvented the process, making it extra flexible and effective. Today, screen printing is widely utilized in numerous markets, from fabrics to signage, showcasing its enduring significance and versatility through the ages.

Benefits of Screen Printing

Screen printing supplies various advantages that make it a favored option for lots of companies and artists. One considerable benefit is its versatility; it can be put on different materials such as fabrics, plastics, and metals, enabling a variety of applications. Furthermore, screen printing provides lively colors and sharp images, making sure top notch results that attract attention.

Applications of Screen Printing

Applications of screen printing vary, extending different markets and objectives. This flexible method is widely used in fabrics, permitting vivid designs on apparel, hats, and accessories. In the marketing products field, companies often rely upon screen printing to develop customized products such as carryall, canteen, and banners, improving brand name visibility.

In addition, screen printing discovers usage in electronic devices, where it is employed to apply conductive inks on motherboard. The automotive market additionally takes advantage of this method, using it for attractive components and security tags. Furthermore, the art neighborhood accepts screen printing for producing restricted edition art work and posters, offering musicians a method to replicate their collaborate with accuracy. The product packaging sector makes use of screen printing for item labeling, making sure that branding is both appealing and long lasting. Generally, screen printing's versatility makes it a necessary tool across many areas.

The Screen Printing Refine

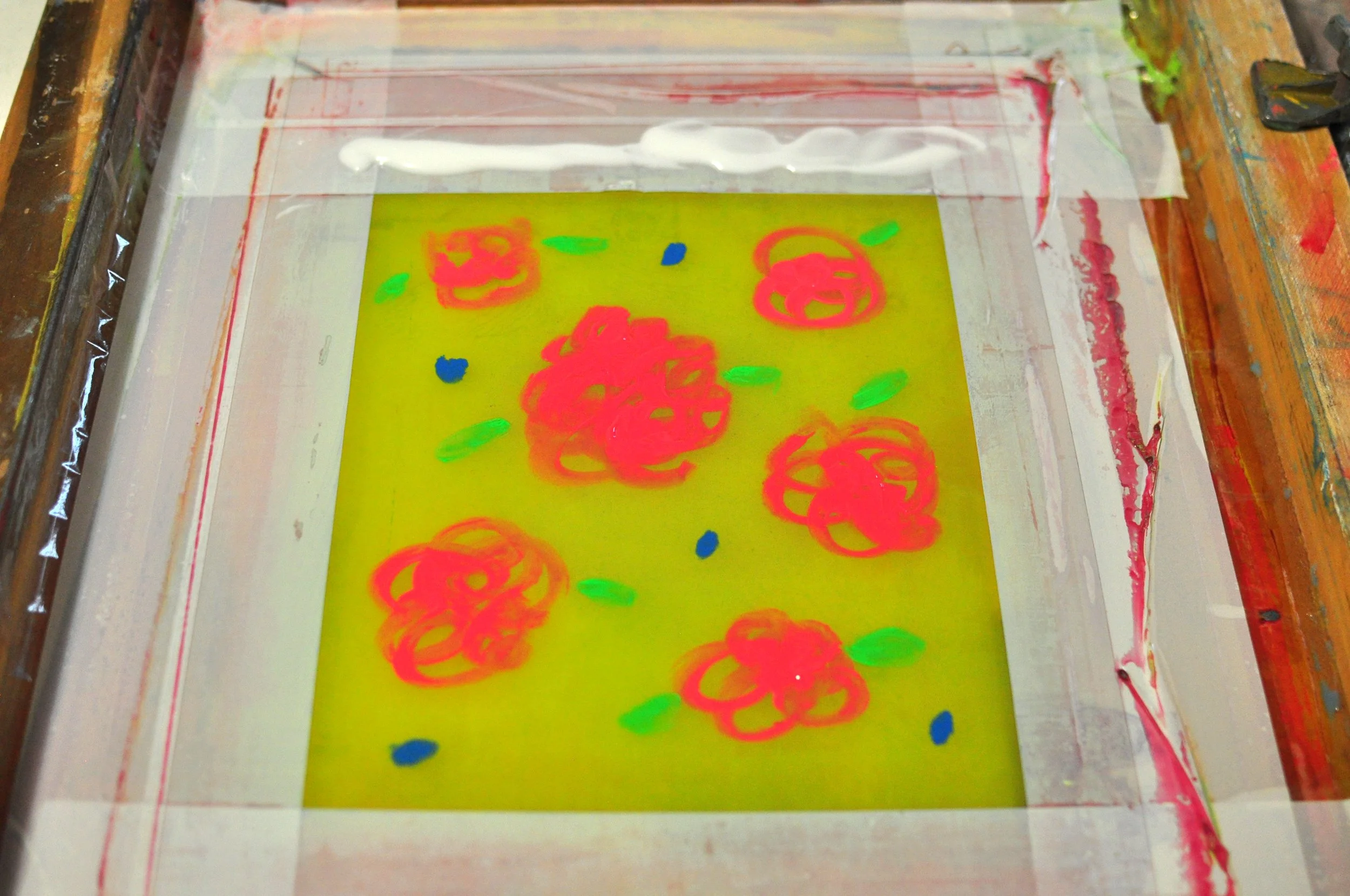

Comprehending the screen printing procedure includes several key actions that change a design into a substantial item. At first, an image is developed and 10:9 Design Abilene after that moved onto a screen, which is generally made of a great mesh product. A stencil is applied, permitting only particular areas of the screen to pass ink. Next, the screen is positioned over the substrate, whether it be material, paper, or one more product.

A squeegee is after that made use of to push ink with the open locations of the stencil onto the substratum. This procedure can be duplicated for multiple shades, requiring specific positioning for each layer. After printing, the product generally goes through a healing process to establish the ink, making certain durability and vibrancy. This methodical approach makes screen printing a reliable and flexible technique for generating premium layouts on a variety of products, catering to both creative and commercial requirements.

Tips for Getting Going With Screen Printing

Beginning on a display printing trip can be both tough and amazing for newbies. To ensure a smooth introduction, it is vital to start with the appropriate equipment. Purchasing a standard screen printing kit can supply essential tools without overwhelming prices. Newbies need to also familiarize themselves with the screen printing procedure, consisting of preparing displays, blending inks, and appropriate printing techniques.

Connecting with other screen printers, either online or in local workshops, can give support and inspiration. Ultimately, maintaining a tidy work space and arranging materials can enhance the printing process, making it a lot more pleasurable and effective. With patience and method, novices can find success on the planet of screen printing

Frequently Asked Concerns

What Products Can Be Utilized for Screen Printing?

Screen printing can use different products, consisting of cotton, paper, polyester, and plastic. In addition, inks such as water-based, plastisol, and discharge are typically used, enabling for varied applications throughout fabrics, product packaging, and marketing products.

How Much Time Does Screen Printing Last on Attire?

Screen printing can last a number of years on garments, relying on factors like ink quality, fabric type, and care directions. Appropriate washing and taking care of greatly enhance the resilience, guaranteeing the design stays dynamic gradually.

Can Screen Printing Be Done at Home?

Yes, screen printing can be done at home. With the ideal equipment and materials, people can create personalized layouts on various garments, enabling personal expression and imagination in their projects without requiring professional services.

What Is the Cost of Setting up a Screen Printing Organization?

Establishing up a screen printing service normally sets you back between $2,000 and $10,000, depending on devices quality, products, and work area. Extra expenses consist of advertising, energies, and continuous products, which can greatly affect general investment.

Just how Do I Clean Screen Printing Screens?

To cleanse screen printing screens, one must use a solvent to get rid of ink, adhered to by a pressure washing machine or hose to remove residue. Lastly, a gentle scrub with a brush assures that screens stay in perfect problem.

In the 20th century, screen printing got appeal in the United States, particularly with the surge of commercial printing and marketing. In addition, screen printing finds usage in electronics, where it is utilized to use conductive inks on circuit boards. Recognizing the screen printing process involves several key actions that transform a layout right into a tangible item - 10:9 Design LLC Company. Screen printing can last a number of years on garments, depending on variables like ink top quality, fabric type, and care directions. To clean up screen printing screens, one must utilize a solvent to get rid of ink, complied with by a pressure washing machine or pipe to eliminate residue